YOUR DESIRED MACHINES

CATEGORY

MODULAR FURNITURE MACHINERY

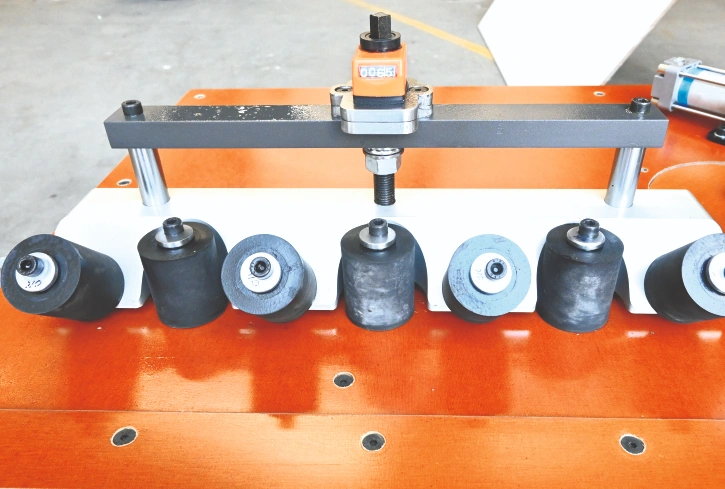

MANUAL EDGE TAPING U-1006

INHANCE PRODUCTION BY OUR MANUAL DGEBANDER

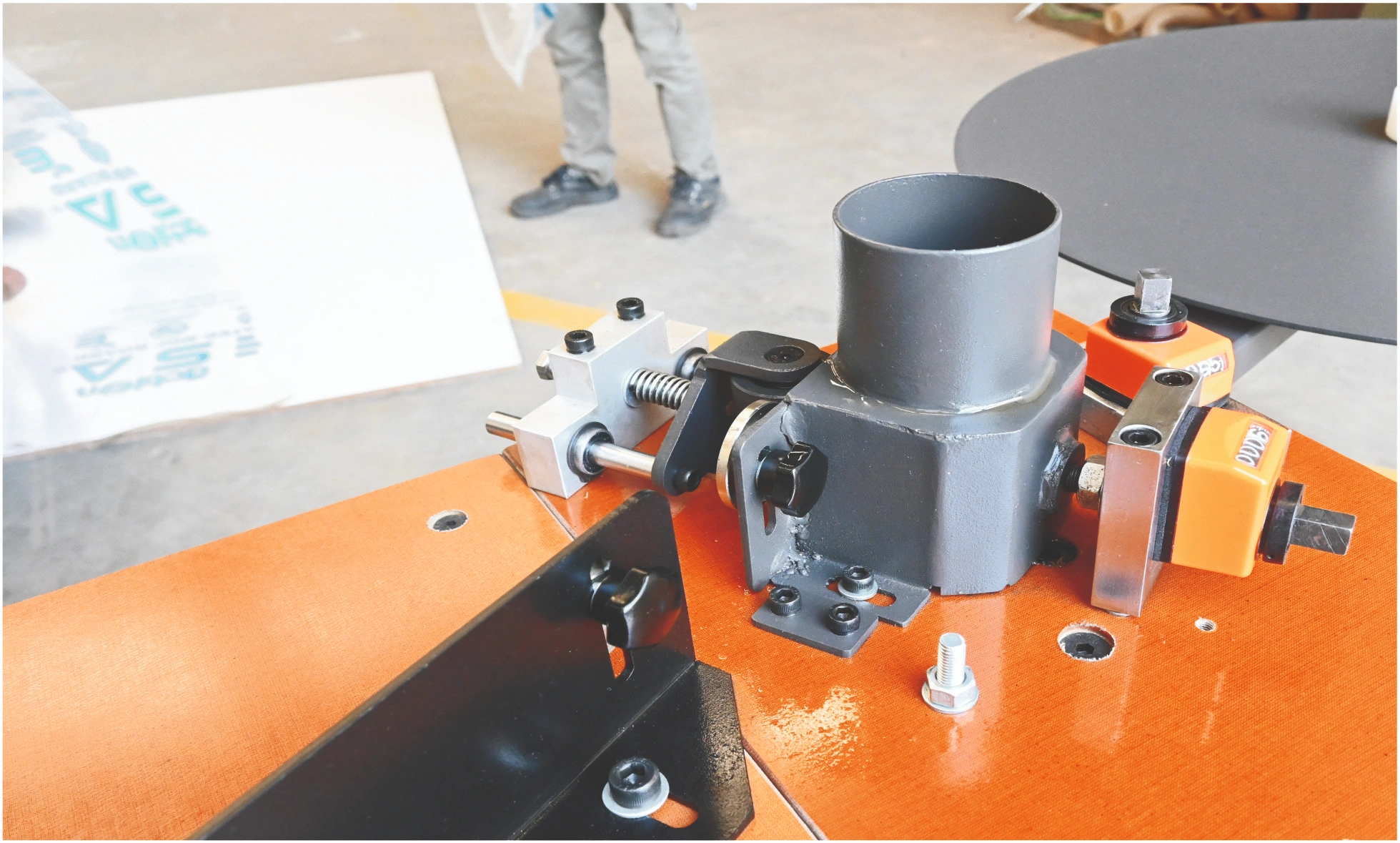

MANUAL EDGE TAPING U-1006-45°

INHANCE PRODUCTION BY OUR MANUAL DGEBANDER

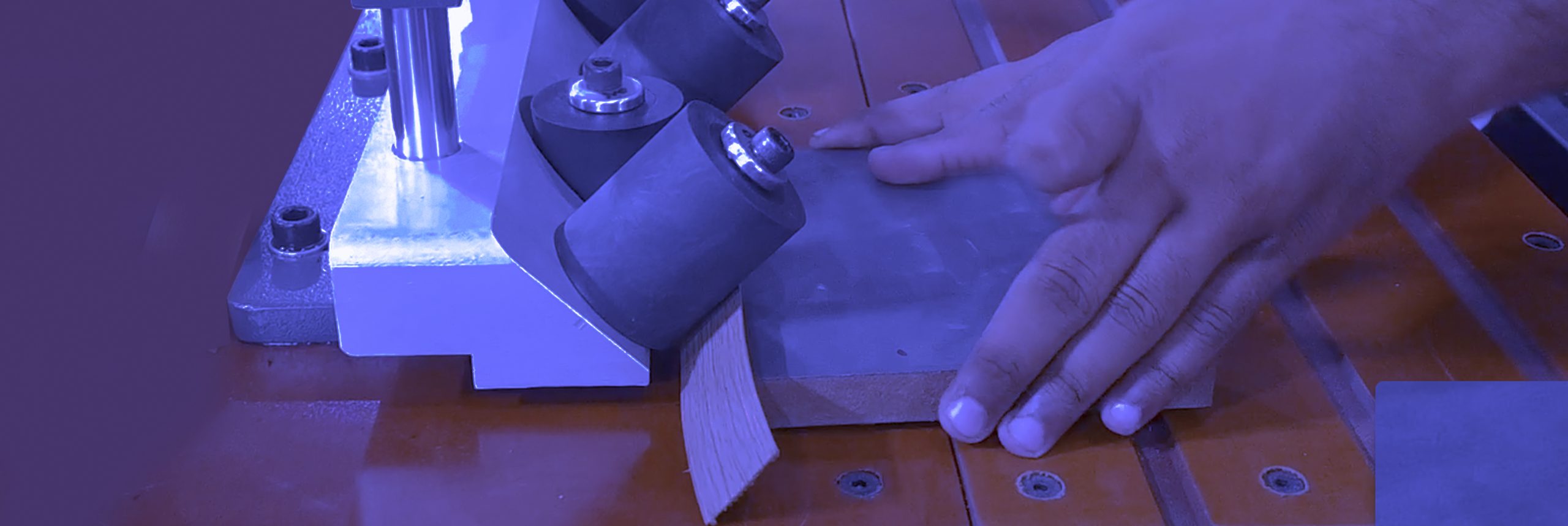

MANUAL EDGE TAPING U-1009

INHANCE PRODUCTION BY OUR MANUAL DGEBANDER

Have Any Question ?

WE ARE HAPPY TO HELP !

About Manual Edge Bander

Buy Manual Edge Banding Machine today for precise, efficient edge banding and superior performance in your woodworking projects. Manual edge banding machines are designed for hands-on application of edge bands, providing flexibility for custom or small-scale projects. They require operator involvement for applying, trimming, and finishing edges, offering a cost-effective solution for lower production volumes. While less automated, they allow for precise control and adjustments based on specific project needs. As a premier manufacturer of Manual Edge Banding Machine, we ensure top-quality machinery for precise and efficient edge banding.

Application of Manual Edge Bander

- Adjustable Settings: Manual edgebanding machines offer adjustable settings for edge thickness and material, allowing for customization based on specific project needs.

- Hand-Operated Controls: They feature hand-operated controls for precise application and trimming of edge bands, providing direct control over the finishing process.

- Versatility: Capable of handling various edge materials, such as PVC, veneer, and laminate, making them suitable for a wide range of applications.

- Compact Design: Generally smaller and more portable than automated models, ideal for smaller workshops or custom woodworking tasks.

- Cost-Effective: Typically more affordable than automatic machines, providing a budget-friendly option for low to medium production volumes.

Advancements:

- Improved Mechanisms: Enhanced mechanisms have been developed for more consistent edge application and trimming, reducing the need for manual adjustments and rework.

- Better Adhesive Systems: Advancements in adhesive application improve bond strength and finish quality, accommodating a wider range of edge materials.

- Ergonomic Design: Modern manual edgebanders are designed with ergonomics in mind, offering easier handling and reduced operator fatigue.

- Enhanced Precision: Newer models feature improved alignment and guide systems for more accurate edge banding, leading to higher quality finishes.

- Increased Flexibility: Recent developments include versatile setups for various edge profiles and materials, enhancing the machine’s adaptability for different projects.