YOUR DESIRED MACHINES

CATEGORY

MODULAR FURNITURE MACHINERY

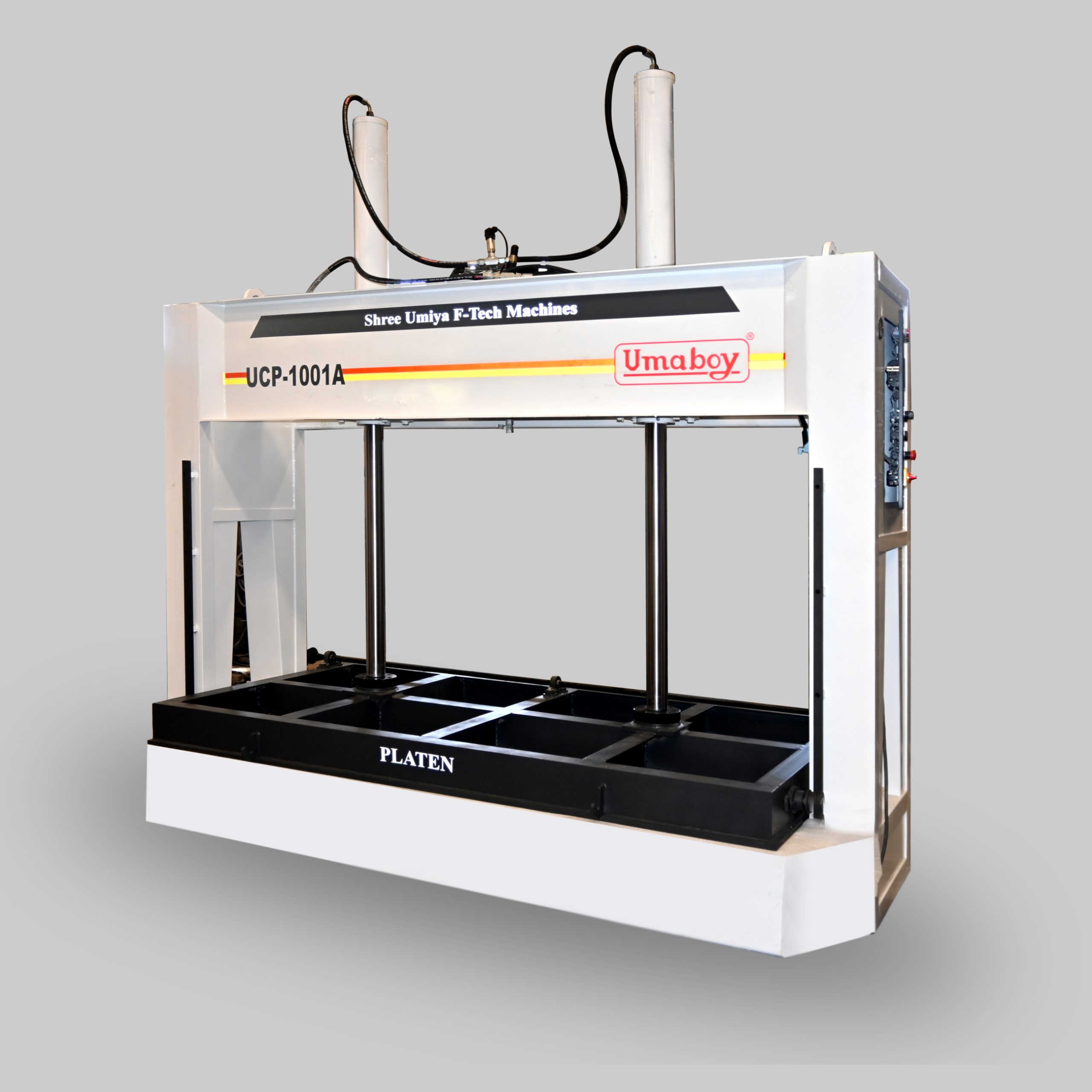

HYDRAULIK COLDPRESS UCP 1001 A

EXPERIENCE THE PRECISION WITH OUR PANEL SAW MACHINES

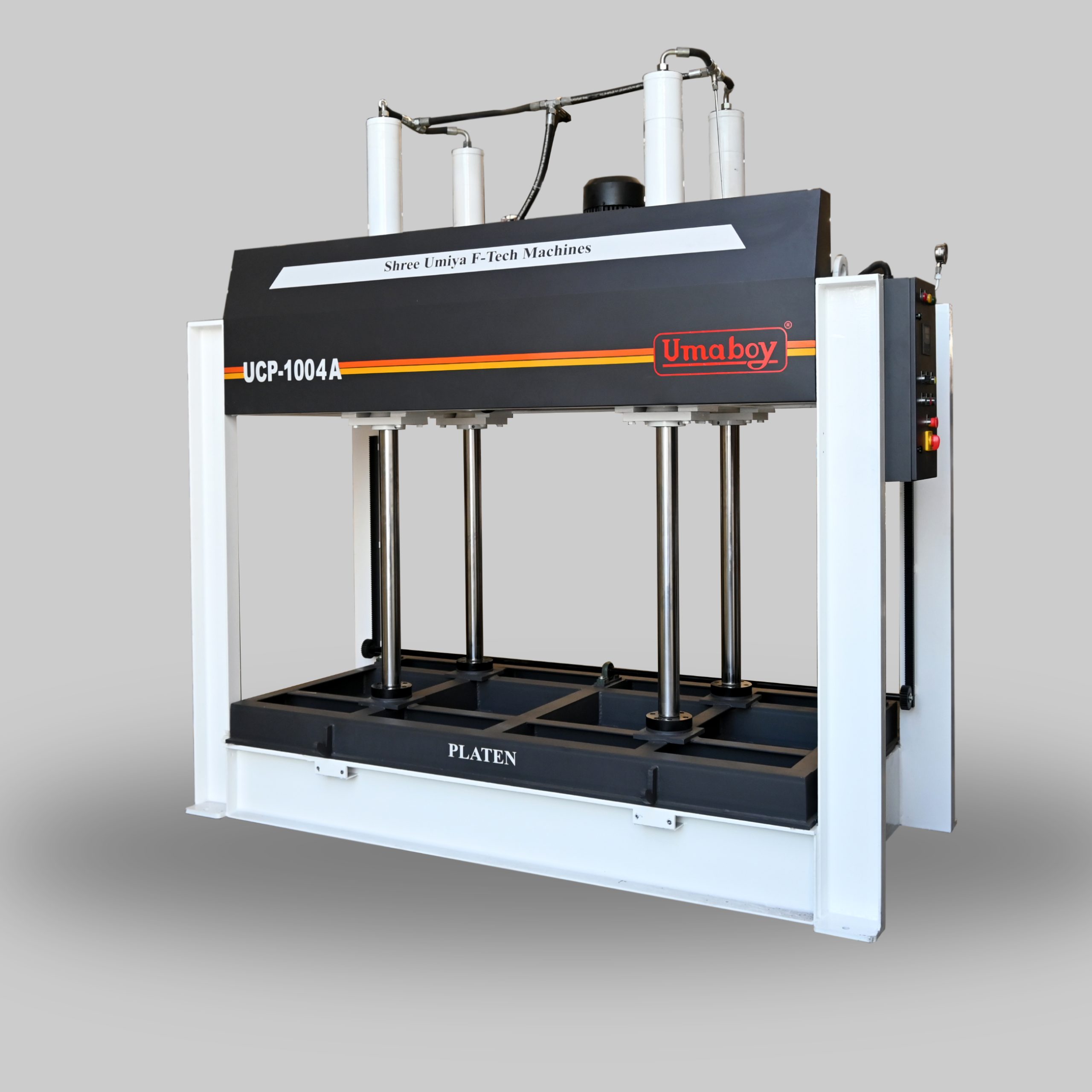

HYDRAULIK COLDPRESS UCP 1004 A

EXPERIENCE THE PRECISION WITH OUR PANEL SAW MACHINES

Have Any Question ?

WE ARE HAPPY TO HELP !

About Hydraulic Cold press Machine

Hydraulic cold press machines apply pressure to materials using hydraulic systems without heat, making them ideal for tasks like laminating and pressing. They offer precise control over pressure and pressing duration, ensuring consistent quality and uniformity. These machines are widely used in woodworking, manufacturing, and composite material production. They efficiently handle large panels and diverse materials, making them essential for high-volume operations. Known for their durability, hydraulic cold press machines deliver reliable performance in various industrial applications.

Application of Hydraulic Coldpress

- Woodworking: Commonly used for laminating wood veneers and creating composite panels, ensuring strong, even bonding without heat.

- Manufacturing: Utilized in various industries for pressing materials like plastics, composites, and paper products, providing consistent results and high-quality finishes.

- Furniture Production: Essential for assembling and finishing furniture components, especially in high-volume production settings where precision and uniformity are critical.

- Composite Materials: Ideal for manufacturing products that require precise pressure application to bond layers of composite materials, enhancing structural integrity.

- Custom Applications: Adaptable for custom or small-scale projects where controlled pressure and high-quality bonding are necessary, offering flexibility in various production environments.

The Hydraulic Coldpress Machine feature and advancement

Features:

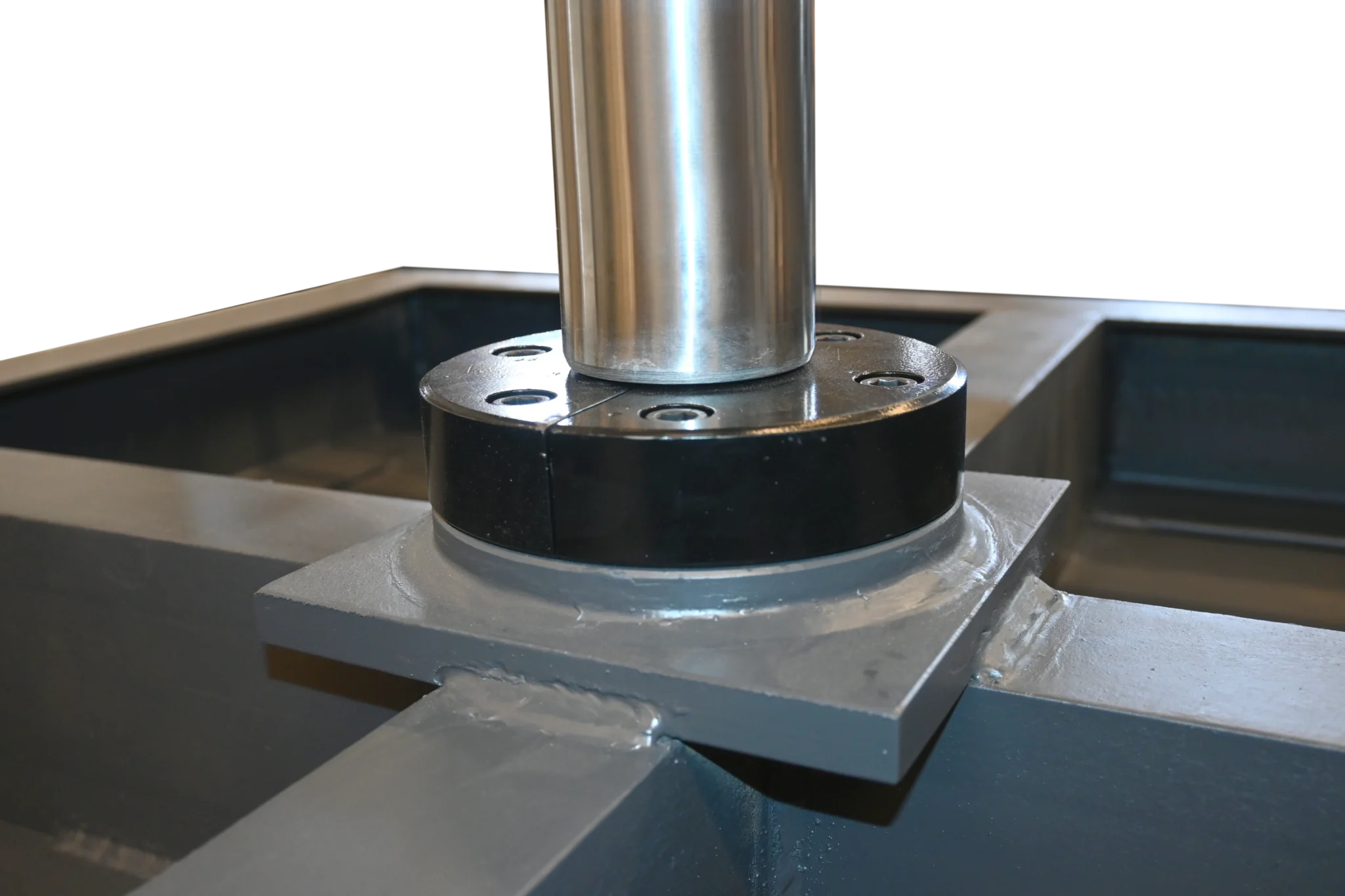

- Hydraulic Pressure System: Uses hydraulic force to apply consistent, controlled pressure to materials, ensuring even bonding and high-quality results.

- Precise Control: Equipped with adjustable pressure settings and timers, allowing for accurate control over pressing parameters and ensuring consistent output.

- Large Pressing Capacity: Capable of handling large panels and various material sizes, making it suitable for diverse applications in woodworking and manufacturing.

- Durable Construction: Built with robust materials and components to withstand high-pressure operations and ensure long-term reliability.

- Versatile Applications: Adaptable to different types of materials, including wood, plastics, and composites, providing flexibility in production processes.

Advancements:

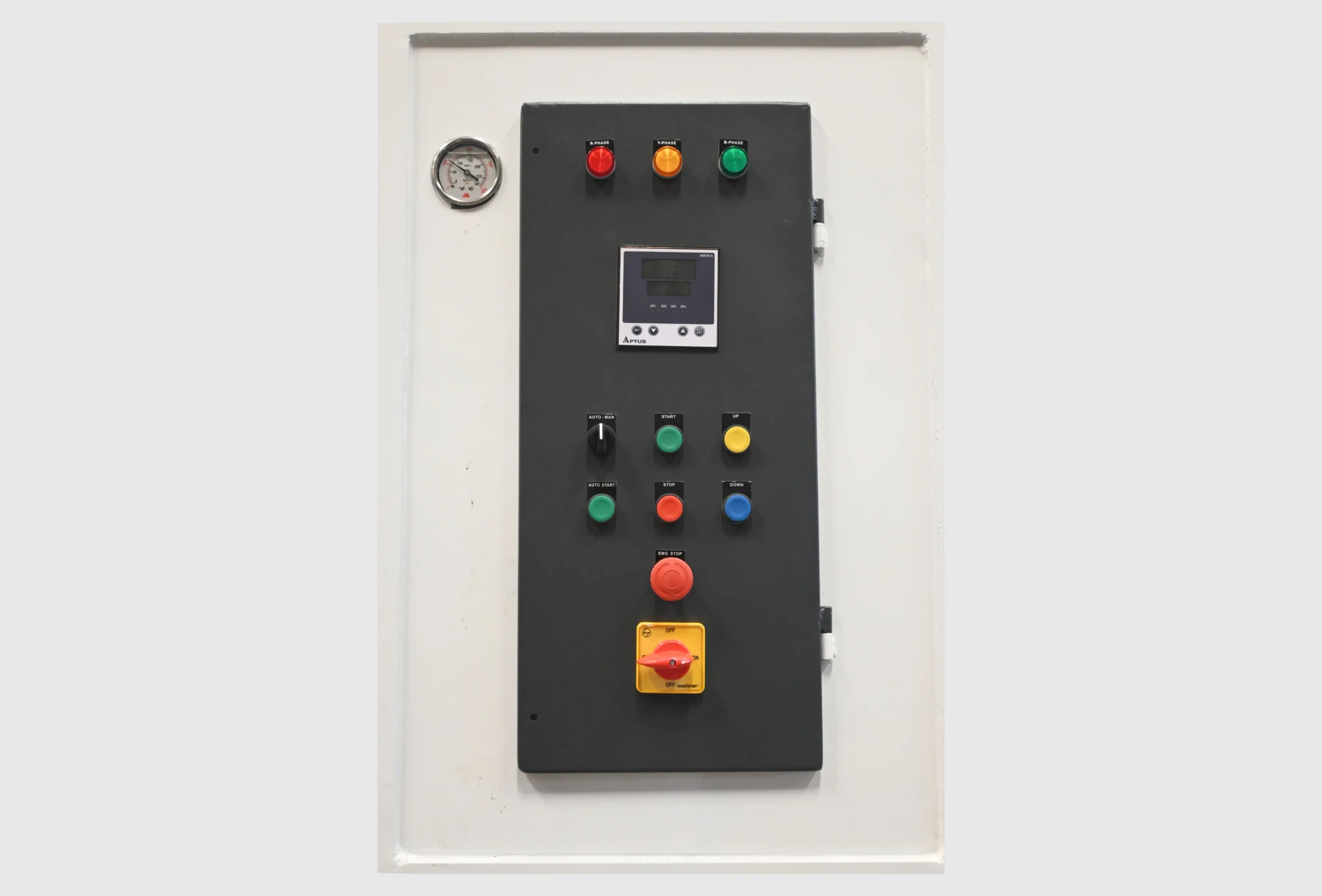

- Digital Controls: Modern machines feature advanced digital interfaces for precise pressure and time settings, improving ease of use and operational accuracy.

- Enhanced Automation: Incorporates automated systems for loading, pressing, and unloading, reducing manual labor and increasing production efficiency.

- Improved Hydraulic Systems: Innovations in hydraulic technology provide more stable and reliable pressure application, enhancing overall machine performance.

- Energy Efficiency: Recent models are designed to be more energy-efficient, reducing operational costs and environmental impact.

- Advanced Safety Features: New safety mechanisms, including automatic pressure relief and emergency stop functions, ensure safer operation and protect both the machine and operators.