CNC Six Sided Drilling Machine

CATEGORY

MODULAR FURNITURE MACHINERY

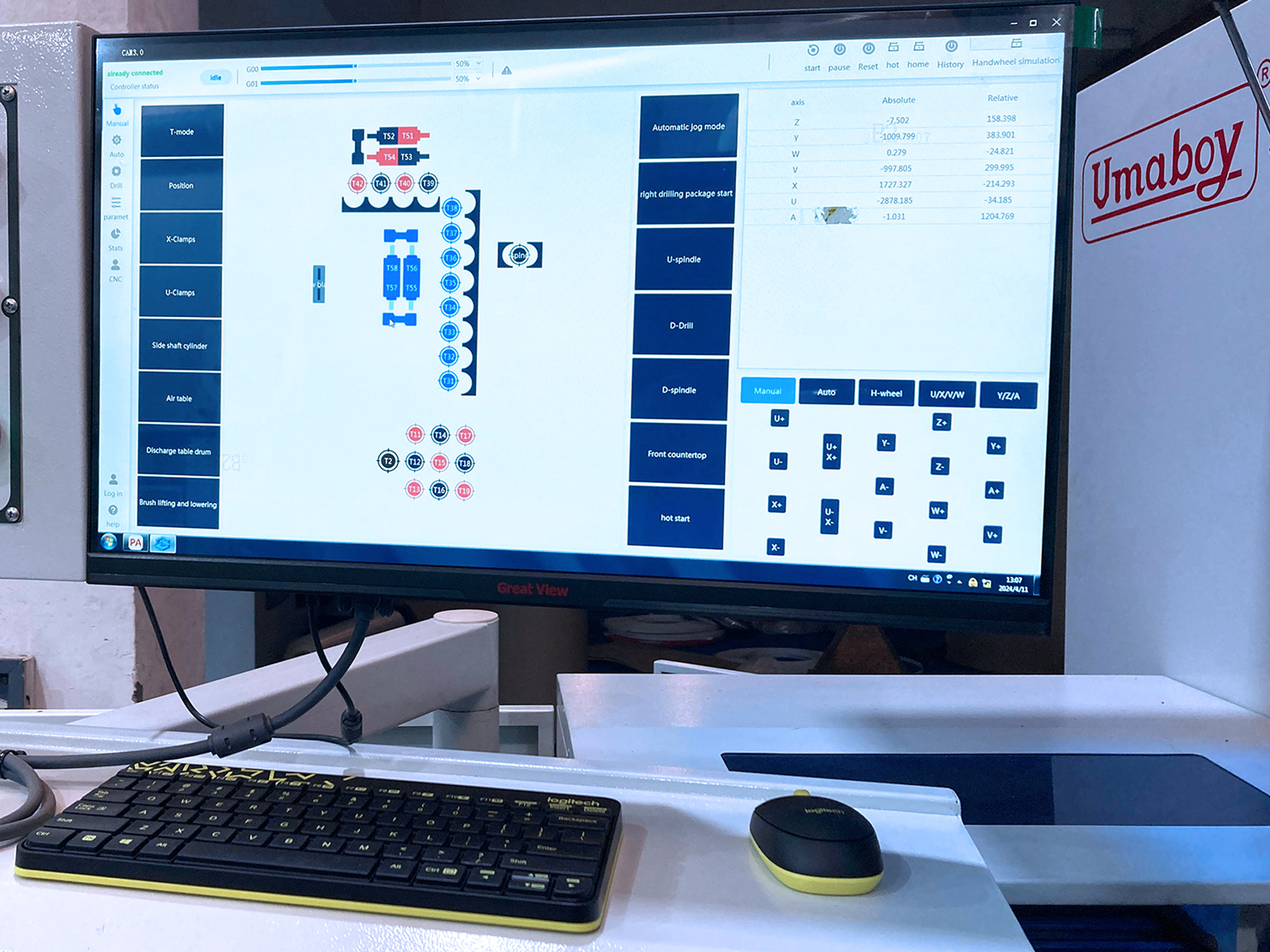

CNC SIX SIDED DRILLING U-612 K

EXPERIENCE THE PRECISION MULTI DRILLING

CNC SIX SIDED DRILLING U-612 KS

EXPERIENCE THE PRECISION MULTI DRILLING

Have Any Question ?

WE ARE HAPPY TO HELP !

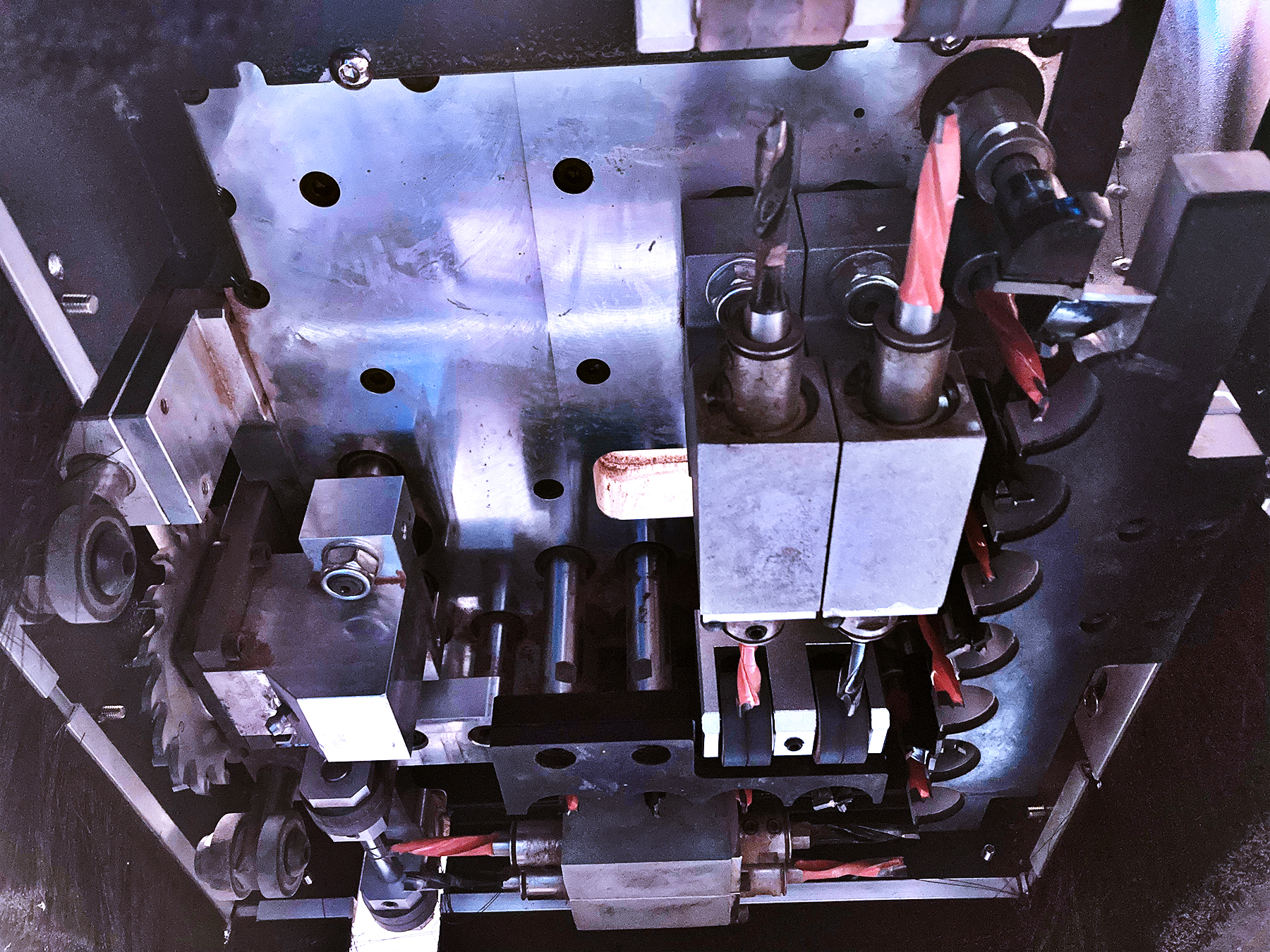

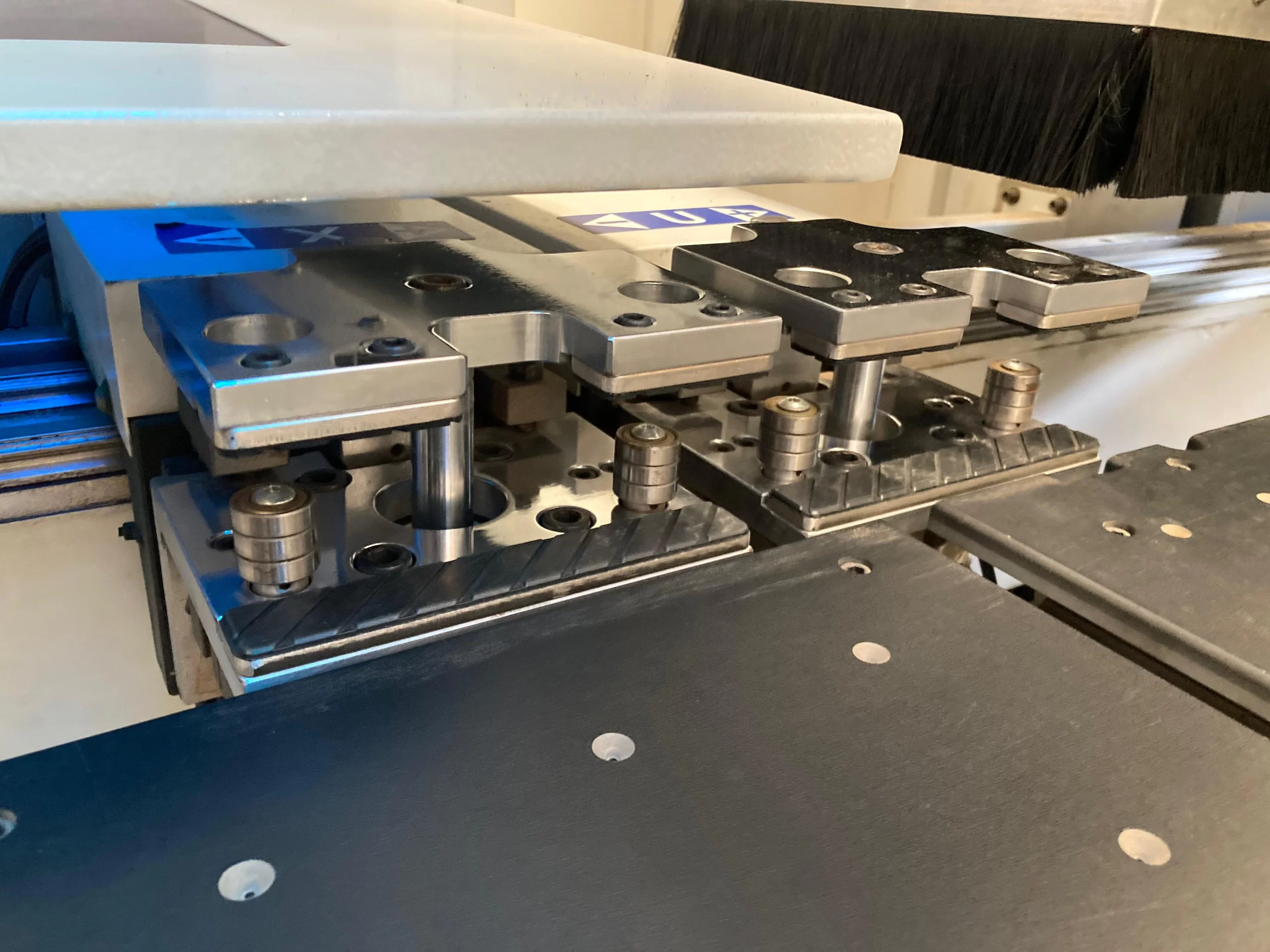

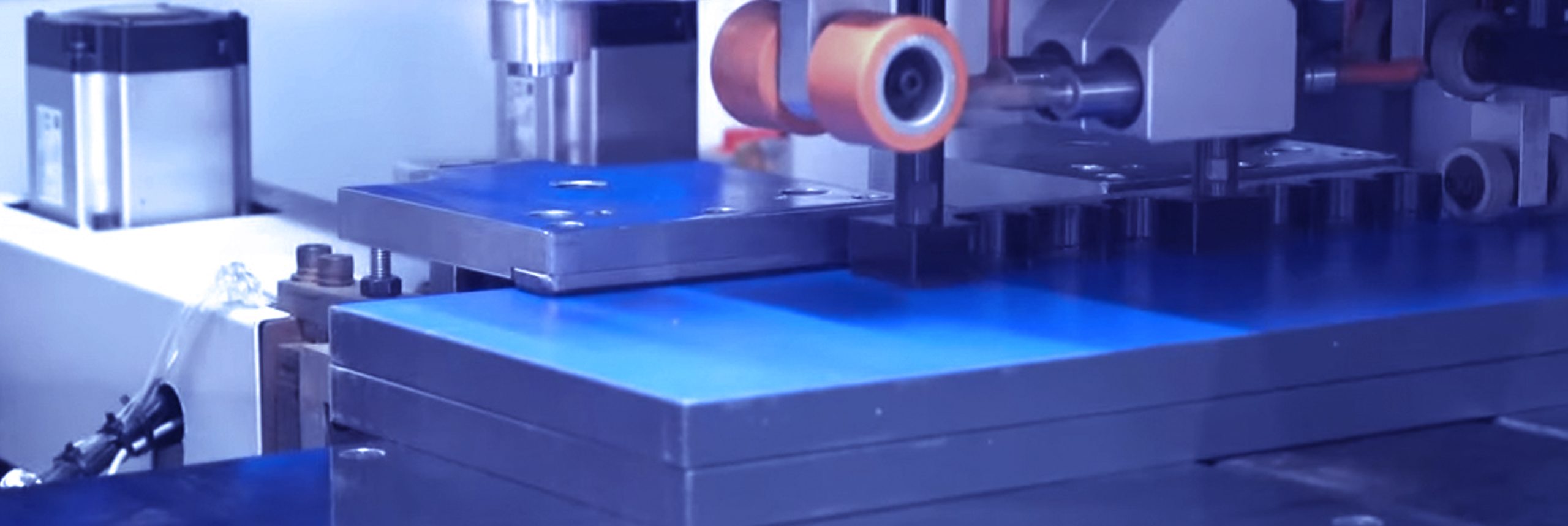

About CNC Six Sided Drilling Machine

UMABOY specifically built this Machine to conduct woodcutting with precision and attention to quality. This may work well for cutting solid wood. MDF board, laminated board, plywood, and particle board. Aluminum alloy that has been utilized in sliding guide panel with first rate power for heavy and hard work. This machines include a Sliding desk of high-power material, making it not likely to bend easily. The UMABOY Panel Saw 3200A is specifically engineered for precision woodcutting, The machine features a high-strength aluminum alloy sliding guide panel, providing exceptional durability and power for heavy-duty applications. Additionally, the sliding desk is constructed from a heavy material.

Application of CNC Six Sided Drilling Machine

- Precision Cutting: Modern panel saws are equipped with advanced measurement systems, including digital readouts and laser guides, ensuring precise cuts with minimal tolerance.

- Adjustable Fence Systems: These allow for quick adjustments to cut various sizes and angles accurately. Some models feature digital controls for exact positioning.

- High-Power Motors: Powerful motors provide the capability to cut through thick and dense materials efficiently.

- Dust Collection: Integrated dust extraction systems maintain a clean work environment by capturing sawdust and debris during operation.

- Safety Features: Enhanced safety mechanisms include blade guards, emergency stop buttons, and anti-kickback devices to protect operators.

The Panel Saw machine features and advancements

Precision and Accuracy: Modern panel saws offer advanced measurement systems, digital readouts, and laser guides, ensuring highly accurate cuts and minimal tolerance.

Increased Efficiency: Automation features, such as programmable cut sequences and automatic feed systems, streamline the cutting process, significantly boosting productivity and reducing manual labor.

Enhanced Safety: Improved safety mechanisms, including blade guards, emergency stop buttons, and anti-kickback devices, help protect operators and reduce the risk of accidents.

Versatility: Modern panel saws can handle a wide range of materials and thicknesses, including plywood, MDF, and particleboard, making them suitable for various applications in woodworking and manufacturing.

Better Dust Management: Integrated dust collection systems maintain a cleaner work environment by effectively capturing sawdust and debris, improving overall shop cleanliness and air quality.