Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

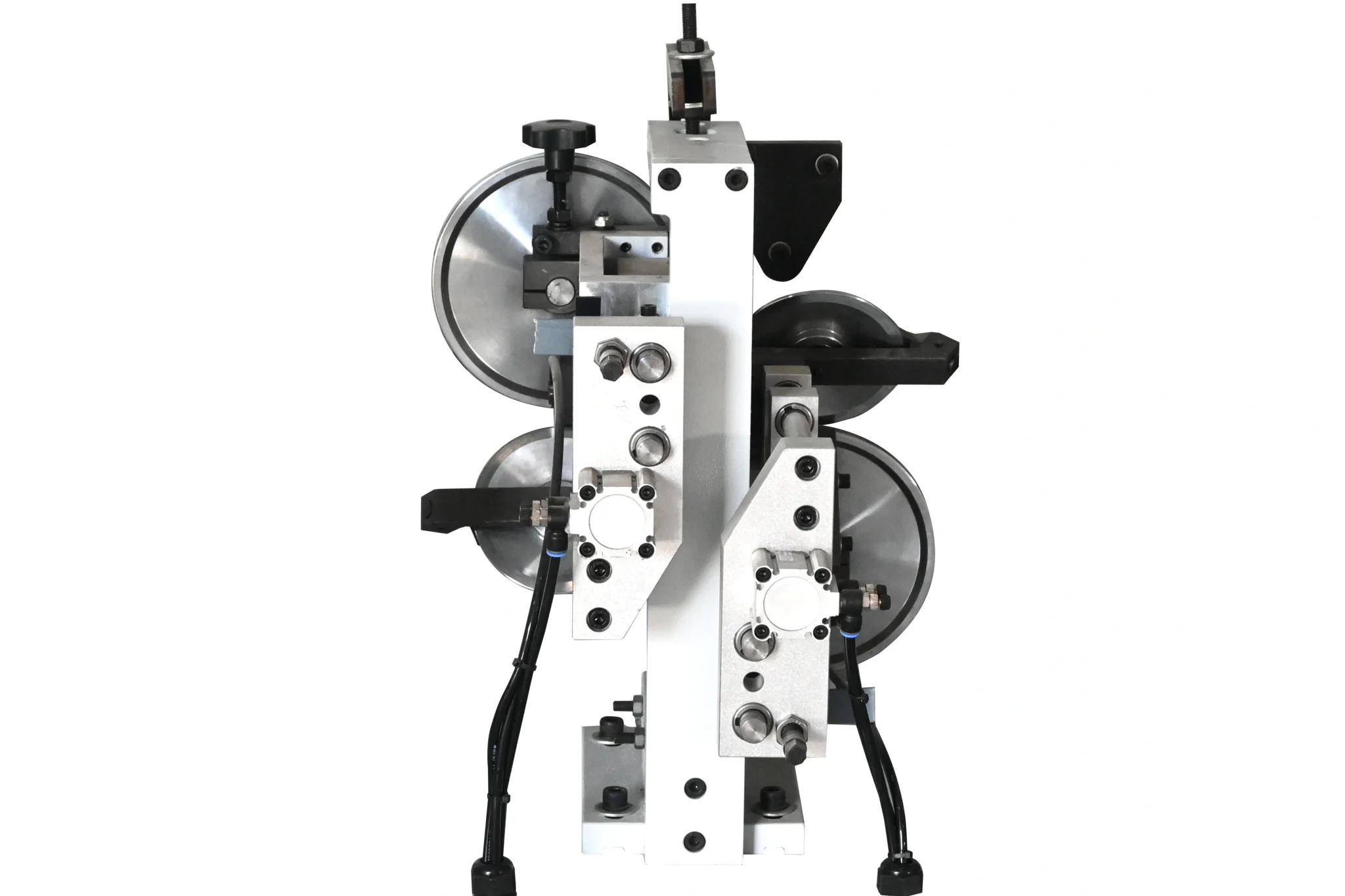

This process guarantees a flawless edge finish, delivering a perfect and professional final appearance.

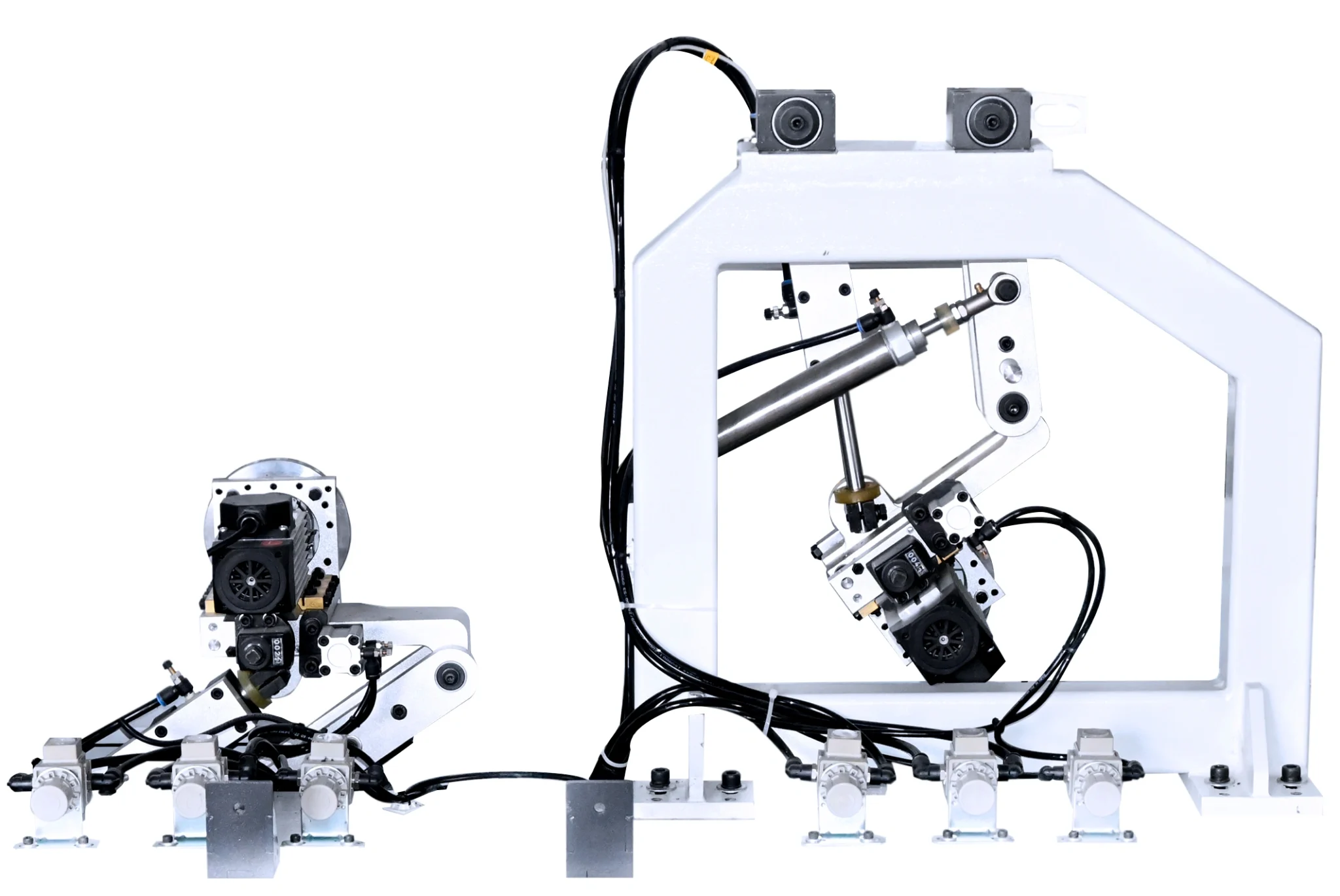

The corner rounding unit ensures precise trimming of the front and rear edges, delivering a perfect, smooth corner finish.

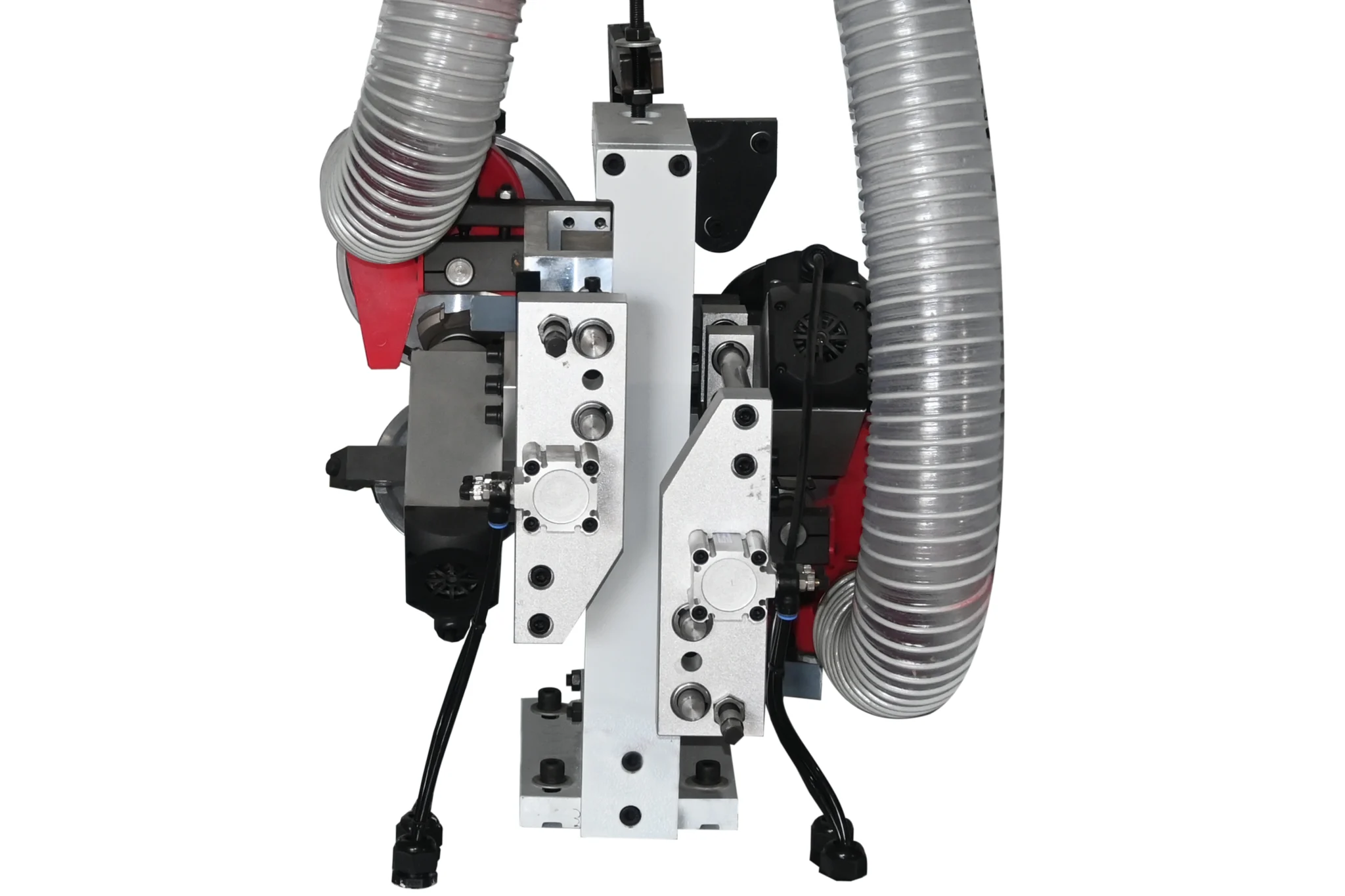

PVC scrapping efficiently removes excess material from the top and bottom edges for a clean, smooth finish.

Includes two R-profile blades, a suction hood, and both front and vertical guide plates for precise and efficient edge trimming.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Contact No:+91 8320070618

Website : www.umaboy.com

621, GIDC Estate, B/H Cifet, Phase IV, Vatva GIDC

Ahmedabad – 382445, Gujarat, India